The new Windermere Fire Station (No. 31) in Edmonton, Alberta, proves it can be done – all you need is a big commitment from the city, a great site, and a careful look at what’s overhead (and underfoot).

The Challenge.

The City of Edmonton has set a target to be a carbon neutral corporation by 2040. According to the City, Edmonton has one of the highest emissions levels per capita in the world, citing that 2018 marked 18.5 tonnes of emissions per person, up from 2017 when they reported 15.7 tonnes of emissions per person[1]. In April 2021, the City’s “Community Energy Transition Strategy and Action Plan” was approved – a plan that explicitly commits to, “Emission Neutral Buildings that are highly energy efficient, powered by renewable energy, and create a thriving energy efficiency industry.” (“Edmonton’s Community Energy Transition Strategy & Action Plan”, Page 6.)

But long before this plan was even approved, the City was already making very real strides toward this commitment. In 2017, design for Windermere Fire Station #31 began. The brownfield site held a lot of promise – a plot of land in a new neighbourhood with single family homes surrounding. The vision for this site was simultaneously traditional and yet forward thinking. There was a desire to create a welcoming fire house – an inviting space that speaks less to “emergency” and more to community. But there was also a clear motivation to move forward – to push the fire station to set a new standard for civic buildings in the City of Edmonton.

Right up front, the owner group wanted clear answers and analysis from the full design team: What would it take to achieve net-zero energy? What GHG emissions standard would we be using? What LEED level made sense to pursue? The City’s Action Plan may not yet have been approved, but their commitments (and expectations) were already firm. Working as part of a highly-motivated design team, Smith + Andersen’s mechanical engineers set to work meeting these expectations. Our goal: less visibility, less noise, and more impact.

The Solution.

In between putting out fires…

If you were to just look at a fire station, you might be inclined to think: “This is a pretty simple building.” There’s a place to park the trucks. Probably spaces where the firefighters can relax and “hang out” between service calls. Maybe some bunk beds.

But in reality, to meet the functional needs of the firefighting teams, a fire station holds a variety of different spaces, and the building systems have to be carefully designed to accommodate these nuances. The ventilation and heating needs of the vehicle bays, for example, are not the same as those of the commercial grade kitchen, or the robust fitness area. For the design of Windermere Fire Station, understanding the needs in each of these unique spaces required close collaboration with the owner group and the user group. The dormitory areas, for example, were critical, and had very specific noise and light criteria that had to be considered; when a firefighter has to sleep, they have to sleep, and there can’t be loud equipment humming or rattling overhead or behind the walls.

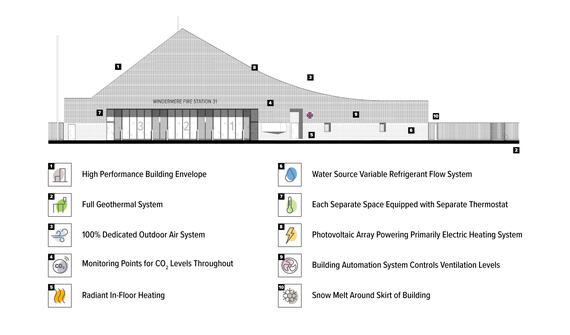

In addition to meeting the functional requirements for each of these areas, we followed ASHRAE 62.1 to make sure that we maintained proper indoor air quality throughout Windermere Fire Station. We incorporated a 100% dedicated outdoor air system (DOAS), which provides good heat recovery as well. Our design followed specific exhaust and ventilation requirements in specialized areas, such as the exhaust component required in the “gear drying” room. Monitoring points for CO2 levels are located throughout the building, and building operators from the City of Edmonton will have the ability to make changes as required.

Big decisions that made a big difference.

Some of the most significant solutions impacting the mechanical design stemmed directly from the City’s sizable commitment. They invested in a high-performance building envelope, and many of the mechanical design options we proposed had elevated efficiency because of this decision.

From the beginning, the City was committed to a full geothermal system – a commitment that is completely out of the norm for a building of this type. A geothermal system offers an eco-friendly approach to building heating and cooling, utilizing the ground, as well as any natural subterranean water movement, as a heat source or sink. By pumping an anti-freeze water solution through buried pipe loops, geothermal fields transfer heat to and from the ground to create cooling and heating through the refrigeration cycle, reducing annual building energy consumption through the storage and re-use of the building’s wasted heat through the geothermal field.

Windermere Fire Station’s geothermal field includes 35 boreholes, and is located in a parking lot next to the Fire Station. Our job was to design mechanical systems using equipment that would align with the parameters of the field – “go between” the field and the equipment. We arrived at a solution that supports this field, with contingencies in place if needed on a particularly cold Edmonton winter day.

The comforts of home…the performance of work

The fire station features a comprehensive heating system with radiant in-floor heating, leveraging the thermal mass of the building’s concrete, in combination with the high-performance envelope design, to create a comfortable, "home-like" atmosphere throughout the station.

To support individual space control, a water source Variable Refrigerant Flow (VRF) system is included, and each separate space in the station is equipped with its own thermostat. This setup will allow the firefighters to adjust heating and cooling as needed, and set back spaces when not in use, optimizing energy efficiency.

The City’s early decision to include a high-performing envelope design significantly reduced space heating and cooling loads. The apparatus bay – which demands extensive ventilation and rapid reheating due to the large bay doors – utilizes hydronic unit heaters designed for compatibility with the low temperature heating system. Meanwhile, the building automation system controls the ventilation levels through demand control and a variable speed ventilation system, effectively minimizing ventilation loads.

Each of these systems are also integrated into the building's geothermal system. Water-to-water heat pumps connect to the boreholes located below the parking lot, providing heating and heat rejection during summer months. Additionally, the station's primarily electric heating system is powered by an extensive photovoltaic solar array on the roof, providing a sustainable energy source for the facility.

Our design also extended to the exterior of the building. Snow melt was required around the skirt of the building, so that there would be no possibility of the vehicle bay doors freezing up in colder temperatures (which are all too common in Edmonton). In order to support this, our design had to achieve a higher water temperature than what we would be able to deliver through standard water to water heat pumps. Our team was careful about equipment selection to make sure that we could achieve the higher temperature necessary to make the snow melt work.

Fitting it all in.

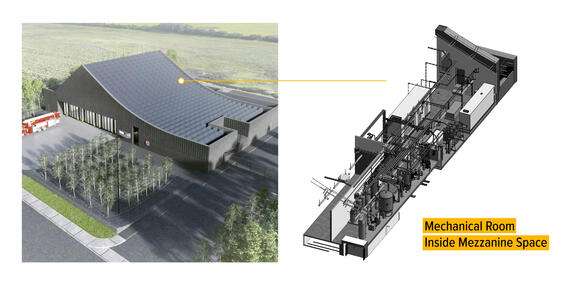

To support the heating and cooling, we were able to mostly use the small refrigeration lines; any other space or connections we needed, we included under slab. In fact, the goal for our design throughout the facility was to do as much as we could with less space.

The mechanical room in the fire station could be considered smaller than what is typically required for a facility this size, but we intricately incorporated what we needed to within the space, keeping systems organized so that maintenance and operations would be as straightforward as possible. The design team went to great lengths to hide the location of the mechanical room, ultimately deciding on a small mezzanine space that followed the curvature of the roof. This posed additional, unique challenges to equipment selection and planning of the mechanical services.

The Result.

Construction of Windermere Fire Station #31 is now complete, and some of the successes are obvious. The architecture, designed by gh3* and S2 Architecture, is every bit the traditional fire hall…but with a modern twist. Public art is planned for the front of the building. The tented roof is both aesthetically reminiscent of an old fire hall, and also the ideal place to host a photovoltaic array on the south-facing slope.

But there are also the less obvious successes – or at least the successes you can’t see when you pass by. As a net-zero building, the total amount of energy used on an annual basis is equal to the amount of renewable energy created on site. The station is also designed to achieve LEED Silver certification and uses 80 kilowatt-hours per square meter per year for heating needs. In addition, the station is designed to perform 40% better than the National Energy Code for Buildings (NECB) 2011, and 40% better GHG emissions using that same baseline.

And then there’s the big win: after the City clearly set their goal more than six years ago, Windermere Fire Station #31 is the City’s first net-zero energy building. A testament to a hugely collaborative team effort…and a signal that change is on the horizon.

To read more about this project, CLICK HERE.